Superheat SmartWay™:

The Leader Among Preheat and Post Weld Heat Treatment Companies

The Superheat SmartWay™ integrates remote operation technology with electrical resistance and induction equipment, combined with our digital project management and QA platform. This integration delivers the most efficient, state-of-the-art, on-site heat treatment services, offering a range of additional applications:

• Post Weld Heat Treatment

• Preheating

• Solution Annealing

• Post-Bake / Bake Out

• Line Thaws

The Superheat SmartWay™ Solution

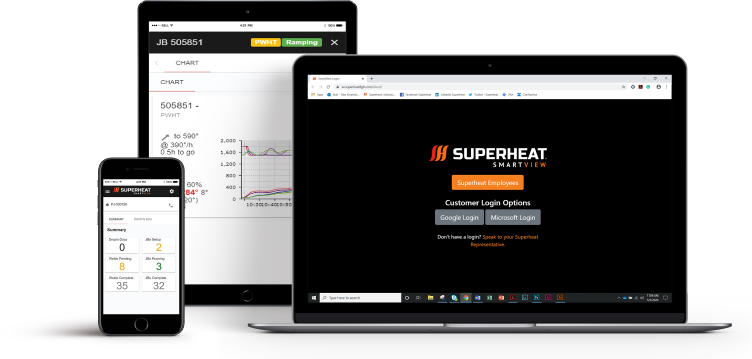

Hover over an icon to download the corresponding datasheetDownload the corresponding datasheet from the list belowSuperheat SmartView™: Your All-in-One Digital Hub for Project Efficiency and Quality Management

Seamlessly manage projects, streamline documentation, and enhance communication between contractors and owners—all from the palm of your hand.

• Setting the benchmark for post weld heat treatment companies, Superheat collects, organizes, and executes all on-site heat treatment tasks using the drop-in box feature. You can leverage the document portal to the Superheat SmartCenter™ throughout your project to maximize productivity of on-site labor.

• Turn data into knowledge so you and other contractors can make informed decisions on the critical next steps of your preheat and post weld heat treatment services. Receive real-time status notifications for estimated heat cycle start and finish times, monitor live heat cycle charts, and more from your fingertips.

• Optimize quality throughput and control of Superheat SmartReport™ packages by downloading cycle charts, Brinells, and other supporting documentation from Superheat SmartView™, or digitally receive them in any format applicable to your system.

The Superheat SmartCenter™

Improve on-site efficiency with our patented remote operation of equipment—trusted as the leader among preheat and post weld heat treatment companies worldwide.

Industry-Leading On-Site Heat Treatment Equipment

In-house manufacturing and a commitment to research & development

As the leader amidst post weld heat treatment companies, we continually invest in R&D to deliver the industry’s most advanced, safety-certified equipment. We recognize the pressure to do more with less—that’s why we design and manufacture heat treatment solutions that maximize efficiency while minimizing their footprint on your project.

Superheat SmartPoint™ (1) and Superheat SmartGen™ (2) preheat and post weld heat treatment consoles employ a patented remote operating process through our Superheat SmartCenter™, increasing the efficiency of on-site crews, allowing them to focus on setup and teardown activities.

Don’t put on-site teams at risk during emergency situations. Superheat SmartPoint™ (1) and Superheat SmartGen™ (2) are engineered to remotely shut down or start up in any environment.

Less equipment to handle more scope through the utilization of the highest capacity zone control per console when compared to any competitor.

Commercial grade dedicated compliant with CLASS 1 Nuclear Program and the only post weld heat treatment services that are approved to UL# 508A/CSA #C22 No.14-10.

Superheat SmartPak™ (3) provides intelligence at the work piece such as component fault indicators, a traffic light technology system for welders, and real-time temperature monitoring, all benefitting the quality of preheat and post weld heat treatment services.

Minimize the risk of electric shock to personnel as the Superheat SmartCard™ (4) in conjunction with near-field technology from the Superheat SmartPak™ (3) creates safety lock-out capabilities directly at the weld location.

For specific scope, the Superheat SmartFurnace™ (5) is an adaptable and on-demand post weld heat treatment service that can meet your immediate needs without wasting money on added logistics.

Superheat has sourced magnets in which their electromagnetic field are minimally affected by standard preheat and PWHT temperatures. The integration of these magnets into the traditional flexible ceramic pad heater has created the Superheat MagneMat™ (6), eliminating the requirement for pins during the onsite stress relieving setup process entirely. The results of this advancement will have substantial cost and schedule savings to your projects bottom line.

In need of induction heat treatment? In partnership with Miller Electric Mfg. LLC, we have leveraged our combined knowledge, data, and technology to amplify the usability, digital quality management, and field-level support of your Miller ProHeat™ 35 induction heating consoles (7). The NEW Superheat SmartLink™ seamlessly programs ProHeat™ 35 units, integrates data into your quality management system, provides access to engineered drawings and videos, and much more. To learn more about our induction services, click here.

Need a centralized project management center? The Superheat SmartShak™ (8) offers the physical electronic components necessary to display Superheat SmartView™ so all disciplines can collectively view real-time project data and make critical decisions.

📢 In Partnership with Miller Electric, We Bring You an Enhanced Induction Rental Experience

We have leveraged our combined knowledge and technology to amplify the usability, digital quality management, and field-level support of your rented Miller ProHeat™ 35 induction heating consoles.